The pace inside the branch lifts around mid-November. Customers request updates earlier, installation windows tighten, and distributor teams shift into a more coordinated rhythm as the holidays approach. A late-afternoon request for 4,500 feet of a specific VNTC tray cable construction is a familiar reminder that year-end activity concentrates quickly. The contractor needs a clear update to keep their installation window steady, and the distributor wants the same clarity to provide a confident quote.

These moments become more common as the year closes and customers consolidate the work remaining on their calendars. Specialty cable adds an extra layer of complexity because availability varies by construction, footage, and origin. During November and December, when working days narrow, distributors benefit from a sourcing structure that emphasizes clarity and reduces uncertainty.

Why This Matters: Understanding the Seasonal Compression on Specialty Cable

Several predictable forces converge during the final weeks of the year and influence the sourcing pace.

Budget Liquidation

Many organizations operate on annual budgets and complete approved work before January. This naturally moves increased material requests into November and December.

Weather and Downtime Windows

Outdoor installations and temperature-sensitive work are often moved earlier to stay ahead of winter. At the same time, commercial and industrial facilities take advantage of scheduled holiday shutdowns to complete major system upgrades. These fixed windows create situations where schedules cannot shift.

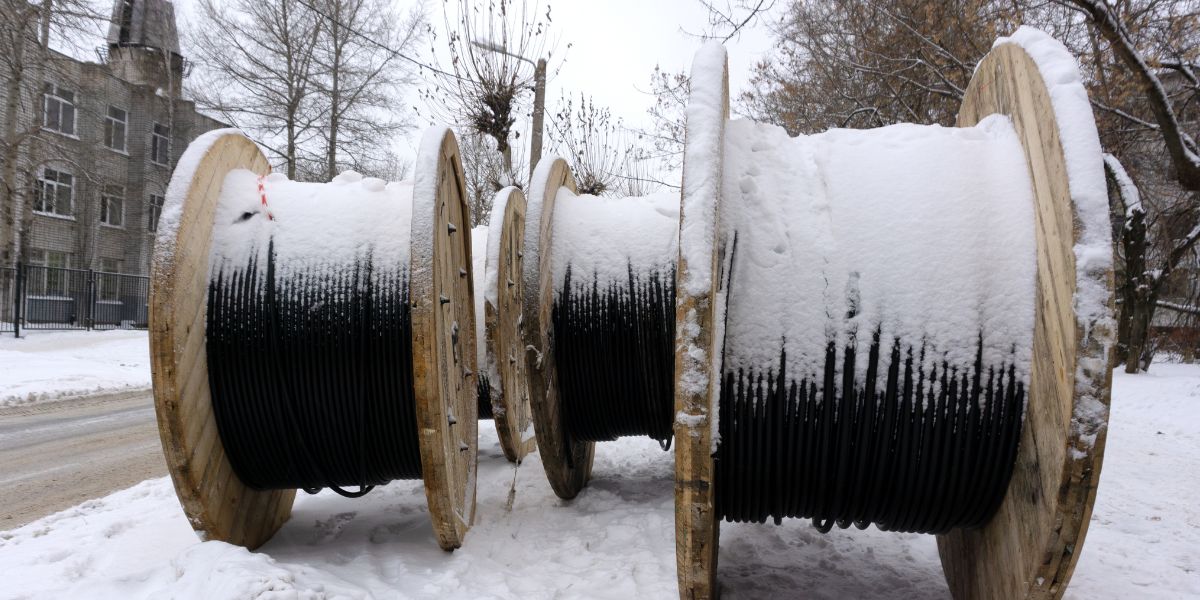

International Production Cycles

Many specialty constructions including MV-105 and VNTC tray cable originate from international manufacturers. These items follow longer production and transit timelines—commonly six to eight weeks—and year-end schedules reduce flexibility even further. Distributors typically do not source directly from overseas plants, but they still need clear visibility into whether a product is available domestically or tied to these longer factory cycles.

This combination makes clarity essential. A hopeful estimate is not enough. The distributor who can confirm the actual path—domestic or international—is the one the contractor relies on, not only for the current request but for the year ahead.

Common Sourcing Pitfalls When Time Is Tight

When timelines are fixed and the installation window is short, it is natural to rely on familiar sourcing approaches. The challenge is that several of these approaches unintentionally add friction or delay at the expense of your relationship and your margin.

The Unconfirmed Lead Time

Providing a delivery estimate based on standard factory schedules or past experience creates uncertainty. Without real-time visibility, any delay becomes the distributor’s responsibility.

The Multi-Supplier Search

Calling several national suppliers hoping one has the exact footage often results in delayed quotes, inconsistent pricing, or inventory located far from the delivery point. Freight delays then squeeze an already narrow installation window.

The Cut Charge Problem

When material is available domestically but only in larger reel sizes, many master distributors apply cut fees. If you absorb the charge, your margin disappears; if you pass it on, the quote becomes uncompetitive.

Each of these approaches slows the process and introduces operational risk. None are suited for year-end conditions where clarity and predictable timing matter most.

A Better Operational Approach: The Dual-Track System for Predictable Sourcing

The most reliable method is a system that distinguishes between two sourcing realities: the Domestic Track (material available now) and the International Track (material that requires factory production). The key is to check the domestic track first, quickly and consistently, with clear visibility.

DWC supports this approach with the operational pieces distributors value most: speed, accuracy, and margin protection.

Track 1: Domestic fastQuote for Immediate Clarity

When a specialty request arrives, the first step is to submit the specification through DWC’s FastQuote channel or directly to your Account Manager.

24-Hour Confirmation: A firm quote and confirmed inventory position are provided within 24 hours or less for standard specialty products. This gives your contractor clarity and gives your team a confident answer to move forward.

No Cut Charges: This is one of the strongest operational advantages. If the cable is in stock across DWC’s strategically positioned CDCs, you receive the exact footage without additional cut fees. This protects your intended margin and removes the uncertainty that complicates specialty pricing.

Same-Day Shipping: When material is confirmed in stock, same-day shipment turns what could have been a six-week factory delay into a two-day delivery.

This process simplifies what could otherwise be a lengthy search. It gives the distributor an immediate answer and allows the contractor to plan with confidence.

Track 2: Transparent International Visibility When Needed

If the exact configuration is not available domestically, DWC provides clear insight into international production timelines based on real-time coordination with established import channels and global manufacturing partners.

This transparency allows you to manage expectations confidently. You can tell your contractor whether the product is domestic, tied to international production, or suitable for a two-stage supply plan.

You receive an accurate timeline and an understanding of production schedules. Clarity replaces uncertainty.

Real-World Win: Meeting a Non-Negotiable Deadline with VNTC Tray Cable

A distributor in the Southeast recently faced a request for 4,500 feet of 4/C 12 AWG VNTC Tray Cable tied to a planned year-end shutdown. Their customer needed the material delivered within the week.

The Challenge

Their first two calls to traditional suppliers produced an eight-week factory lead time and a full reel requirement with a 15 percent cut fee. Neither option met the project deadline or margin targets.

The DWC Solution

The distributor submitted the request through fastQuote.

Within hours, the full 4,500 feet was confirmed in stock at the nearest CDC.

No cut charge was applied.

The order shipped the same day.

The delivery reached the distributor’s branch in under 48 hours. The contractor completed the installation on schedule. The distributor protected their intended margin and strengthened the relationship heading into the new year.

Turning Year-End Pressure into an Operational Advantage

When the year-end rush hits, having a repeatable process matters. These three practices consistently help distributors win specialty business during tight installation windows:

Start with the Domestic Track Every Time: Any specialty request with a firm deadline should immediately enter the FastQuote process. This removes guesswork and eliminates sourcing delays.

Provide Confirmed Information, Not Estimates: If the material is in stock, you can quote a same-day shipping reality. If it is tied to production, you can communicate a clear, accurate timeline. This builds trust and positions you as a reliable partner.

Use DWC as a Low-Risk Specialty Inventory Extension: With strategically located CDCs, strong specialty stock, and no cut charges, you gain operational flexibility without increasing branch inventory.

These three steps help distributors protect margin, respond with clarity, and support their customers during the most compressed time of the year.

For assistance with specialty sourcing, availability questions, or application support during the holiday season, contact your DWC Account Manager or submit a request through fastQuote.